The Role of Robotics in Achieving Sustainable Warehousing

In this blog, we will explore the significant role of robotics in creating more efficient, cost-effective, and eco-frien...

The rapid advancement of technology has revolutionized various industries, and warehousing is no exception. In recent years, robotics has emerged as a game-changer in the field of logistics and supply chain management. With the growing focus on sustainability and environmental responsibility, robotics has become an invaluable tool for achieving sustainable warehousing practices. In this blog, we will explore the significant role of robotics in creating more efficient, cost-effective, and eco-friendly warehousing operations.

Streamlined Operations and Energy Efficiency

One of the primary benefits of incorporating robotics in warehouses is the ability to streamline operations and improve energy efficiency. Traditional warehousing practices often involve extensive manual labor and inefficient processes. Robotic systems, such as automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), can perform repetitive tasks with precision and speed, minimizing human error and maximizing productivity. By optimizing workflows, these robots can reduce the time taken to complete tasks, leading to significant energy savings and lower operational costs.

Space Utilization

Efficient space utilization is crucial for sustainable warehousing practices. Poorly organized warehouses with excessive aisle space and inefficient storage arrangements lead to wastage of energy and resources. A study conducted by DHL and Cisco Systems found that introducing robotics and automation into warehouses can result in a 20% increase in operational efficiency, leading to a 15% reduction in energy consumption and a 30% decrease in carbon emissions. These significant improvements highlight the positive environmental impact of implementing robotics in sustainable warehousing practices.

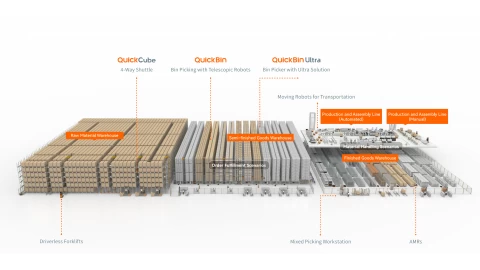

Robotic systems can play a pivotal role in optimizing space utilization through intelligent inventory management. For instance, robotic arms and picking robots can identify and retrieve items with greater accuracy and speed, minimizing the need for excessive safety stocks and reducing storage requirements. Additionally, robots can efficiently navigate narrow aisles and store goods in high-density configurations, making better use of available space.

Environmental Impact

Sustainability in warehousing extends beyond operational efficiency to include minimizing material waste and environmental impact. Robotics can significantly contribute to waste reduction by improving accuracy in handling and sorting processes. Robots equipped with advanced vision systems can identify damaged or expired goods, helping prevent their inclusion in shipments and minimizing waste. Additionally, robots can ensure optimal packaging sizes, reducing the use of excess packaging materials and overall packaging waste. This not only leads to cost savings but also helps preserve natural resources and reduce carbon emissions associated with packaging production.

Workplace Safety

Worker safety and well-being are paramount in any sustainable warehousing practice. Robots can do physically demanding and potentially hazardous tasks, reducing the risk of workplace accidents and injuries. By automating repetitive and strenuous activities, robots free up human workers to focus on more complex and value-added tasks, enhancing job satisfaction and overall employee well-being. Moreover, the integration of robotics can lead to a more ergonomic work environment, minimizing strain on workers' bodies and decreasing the likelihood of musculoskeletal disorders.

Data-Driven Decisions

Robotics in warehousing generates a wealth of data that can be leveraged for data-driven decision making and continuous improvement. Automated systems provide real-time insights into various aspects of warehouse operations, including inventory levels, order accuracy, and equipment performance. By analyzing this data, warehouse managers can identify bottlenecks, optimize processes, and make informed decisions to enhance overall efficiency and sustainability. Continuous improvement efforts driven by data analytics can result in reduced energy consumption, minimized waste generation, and increased overall warehouse performance.

Conclusion

Incorporating robotics into warehousing operations is increasingly becoming a necessity for achieving sustainable practices. By leveraging the capabilities of robotics, warehouses can optimize operations, reduce energy consumption, minimize waste, enhance workplace safety, and improve overall efficiency. As technology continues to evolve, we can expect even more advanced robotics systems and artificial intelligence solutions to revolutionize the warehousing industry further. With the right integration and strategic implementation, robotics will undoubtedly play a pivotal role in shaping the sustainable future of warehousing and logistics.

We firmly believe that robotics is the key to unlocking sustainable warehousing. By automating repetitive tasks, optimizing space utilization, and leveraging data-driven insights, robots not only enhances operational efficiency but also drives environmental responsibility. Our goal is to empower warehouses with innovative robotic solutions that contribute to a greener and more sustainable future.

Wei Yang, CEO- Quicktron Robotics

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.