Super A, Super Fast, Super Storage Highlights from Quicktron’s booth at CeMAT 2024

On November 5, 2024, Quicktron, a leader in hybrid logistics and warehousing, will make its eighth appearance at CeMAT ASIA. For eight consecutive years, Quicktron has showcased groundbreaking solutions that push industry boundaries. This year, it unveils the enhanced QuickBin+ system and the new M5F moving robot, built on a mixed picking and high-density storage solution. With innovations across robots, racks, and workstation design, Quicktron offers audiences a refreshing perspective on mobile automation.

New Product Launch: A Dual Breakthrough in Efficiency and Cost Optimization

As one of the highlights at this year’s CeMAT, Quicktron introduces its next-generation M5F moving robot. This upgraded model boasts major performance enhancements, innovative intelligent operation, and flexible configurations, making it ideally suited to meet dynamic enterprise demands in automated warehousing.

Through technical advancements, the M5F greatly improves picking efficiency and storage capacity within the QuickBin solution. Equipped with a single-column fork arm and dual-layer storage for storing high-demand “A-Category” SKUs, the M5F reallocates high-frequency tasks, reducing robot transport by bin movers by around 20–50%. This innovation optimizes storage and retrieval processes, offering high throughput and minimal downtime, maximizing customer ROI.

The M5F achieves one of the highest movement speeds in the industry, reaching up to 4.5 m/s, ideal for fast-paced, high-throughput warehouses. Additionally, with a robust 11-hour battery life—up to 12 hours under optimal conditions—it minimizes downtime from frequent charging. In an 8-hour shift scenario, single-shift operations won’t require mid-shift charging, improving robots utilization.

In terms of space optimization, even with the upgrade from single-layer to double-layer buffer slots, there’s minimal loss of racking space. The M5F features the industry’s lowest retrieval height, with buffer slots as low as 330mm, enabling users to make full use of every inch of warehouse space. This flexible configuration of single or double-layer buffer slots allows the M5F to serve as a high-performance robot, adaptable to various operational demands.

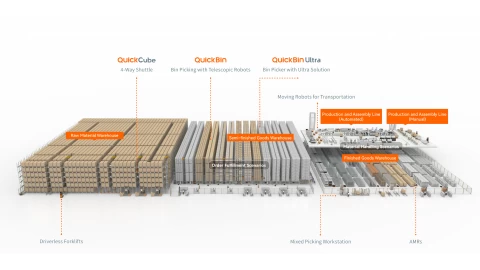

Comprehensive Showcase of the QuickBin+ Mixed Picking Solution

At this exhibition, Quicktron will focus on showcasing the QuickBin+ mixed picking solution. The standout feature of this solution is its integration of various robots capable of handling the transportation of bins, pallets, and shelves, allowing for simultaneous mixed picking of large, medium, and small SKUs.

The QuickBin solution has long been renowned for its high flexibility and efficient cargo handling capabilities, and QuickBin+ further enhances the flexibility of the entire warehousing system. Through multi-machine collaboration, the QuickBin+ solution efficiently covers various operational aspects within the warehouse. It integrates large bin picking robots like the C56, small bin handling robots such as the M5F, and shelf/pallet handling robots M100 (with a 1000kg load capacity) or M1500 (with a 1500kg load capacity). Coupled with mixed picking workstations, it supports multiple operational modes, including “bins to person,” “shelves to person,” and “pallets to person,” significantly improving picking efficiency and inbound/outbound capabilities to meet diverse and variable business needs.

Flexible Combinations of Multi-Machine Collaboration

In addition to the combination of the C56 bin-picking robot and the M5F moving robot, Quicktron will showcase the refined capabilities of multi-machine collaboration at this exhibition. For customers with diverse business scenarios, selecting from Quicktron’s various models allows for a flexible combination options.

- The H80D material-handling robot is specifically designed for faster and narrower aisles, offering exceptional handling capabilities, making it an ideal choice for industries with high demands for precise handling and throughput, such as electronics and PCB sectors industries.

- The M100C shelf/pallet handling robot has a wide range of applications, capable of transporting heavy shelves and seamlessly integrating into complex warehousing systems (such as connecting with conveyors and lifts).

- The F140D is Quicktron's latest smart forklift, designed to meet the demands of high-load and high-frequency operations, particularly suited for manufacturing and heavy industry. Its intelligent operating system supports 360° obstacle avoidance, ensuring safety and stability in complex industrial environments. The interaction between the forklift and the mobile AGV enables complete pallet circulation within the storage area.

Outstanding Example of Multi-Machine Collaboration

Jiangxi Blue Ocean Technology Co., Ltd. is a modern publishing logistics center built by the China Media Group, located in Nanchang, Jiangxi Province, covering an area of 26,357.88 square meters. Quicktron tailored a set of modern warehousing solutions for this project.

The successful implementation of this project marks a breakthrough for Quicktron in intelligent warehousing, creating significant value for its customers. The project includes 44 third-generation moving robots M150, 8 units of H80A moving robots, and 9 units of FD140 smart forklifts, becoming an important milestone for Quicktron in forklift projects. This is Quicktron's first non-stackable forklift project optimizing the communication protocols between AGVs and RCS, thereby enhancing operational efficiency and system stability.

At Jiangxi Blue Ocean Technology, Quicktron’s multi-machine collaboration is achieved through the relay handling of smart forklifts and mobile robots. The specific operational process involves 9 smart forklifts efficiently transporting empty pallets from the first-floor buffer area to the inbound unloading area and transfer points. Through this collaborative operation model, Quicktron demonstrates its innovative capabilities in multi-machine cooperation, significantly improving the efficiency of warehousing and logistics management.

Conclusion

The launch of the new M5F robot and QuickBin+ solution at the 2024 CeMAT exhibition represents cutting-edge innovation in the field of intelligent warehousing. Quicktron will continue to promote "demand-driven" innovations. Moreover, the flexibility and scalability offered by Quicktron's entire product line provide even more possibilities for applications. We look forward to these innovations and upgrades, continually enhancing the flexibility and adaptability of warehousing operations, making our customers' investments more cost-effective. Quicktron will continue to drive the development of intelligent warehousing technology, delivering more efficient and intelligent logistics management solutions across various industries.

Suni develops engaging content, manages impactful social media campaigns, and expertly handles online ads, webinars, podcasts, and video production. She builds strong client relationships by providing support and resources that help drive their sales success. Using a data-driven approach, Suni continually refines strategies and collaborates effectively to stay ahead in the fast-paced digital landscape.