Warehouse Robots: The Droids of Modern Warehousing Realm

The warehousing and logistics industry is facing a myriad of challenges. Warehouse, supply chain, and fulfillment center managers confront soaring order volumes, a dwindling workforce, the call for next-day delivery, budget constraints, and spatial limitations. In this fast-paced environment, traditional and manual processes are no longer enough to meet the demands of modern supply chains. Embracing flexible automation is no longer a luxury; it's a necessity.

Mordor Intelligence predicted that the Warehouse Robotics Market size is expected to grow from USD 6.74 billion in 2023 to USD 15.22 billion by 2028, at a CAGR of 17.70% during the forecast period (2023-2028) (Source). Warehouse robots are emerging as the game-changers in the industry, offering a powerful solution to optimize operations, enhance productivity, and streamline workflows. These mechanical marvels are not just about replacing human workers; they are about augmenting human capabilities and creating a more efficient, collaborative work environment. By grasping their capabilities and the best practices for implementation, you can confidently advocate for robots as a necessity! but how? This blog explores their capabilities and best practices for implementation.

Decoding Warehouse Robots

When picturing robots, you might envision the droids from Star Wars- fictional mechanical beings programmed to perform various tasks and functions in the galaxy far, far away. They were the fictional characters of the film, but you can consider the modern warehouse robots as the droids of the real warehousing realm and are like the inspired descendants of their iconic counterparts from the Star Wars universe. Much like the beloved astromech droids in Star Wars, warehouse robots are equipped with an array of sensors and cameras that enable them to navigate the vast expanse of the warehouse galaxy. Agile and precise, they glide through the aisles, effortlessly avoiding obstacles, just as R2-D2 maneuvered through the treacherous landscapes of Tatooine.

The primary function of warehouse robots is to automate and optimize processes such as order picking, inventory management, sorting, packing, and transporting goods within a warehouse. Warehouse robots can perform these tasks autonomously or be controlled remotely by human operators. Using artificial intelligence algorithms and machine learning capabilities, warehouse robots can continuously learn and adapt to their environment, improving their efficiency and accuracy over time. They can also communicate and coordinate with other robots, machines, and warehouse management systems to enhance overall productivity and minimize errors.

So, the next time you step into a bustling warehouse, imagine the warehouse robots as droids from a distant star system, activated and ready to lend a metallic hand. With a touch of science fiction charm, these industrious automatons bring the magic of a galaxy far, far away into the hum of everyday operations, revolutionizing the warehousing experience one task at a time.

Types of Warehouse Automation

Warehouse automation falls into two major categories:

Fixed Automation: Involving conveyors, AS/RS systems, and similar rigid structures, that are inflexible.

Goods-to-Person (G2P): Typically refers to autonomous mobile robots (AMRs) that bring goods to pickers at workstations, eliminating the need for manual aisle wandering. These systems are modular and flexible and can be scaled as per customer needs.

Choosing the Right Fit

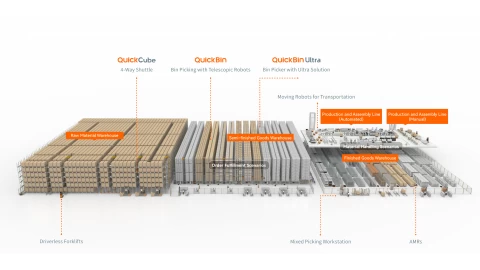

Before deciding on any automation solution, assess your unique warehouse requirements. Choose an option aligned with your needs, whether fixed automation or a more flexible Goods-to-Person system. Quicktron offers diverse G2P automation solutions tailored to cater to various needs based on factors such as warehouse layout, available space, throughput requirements, SKU management, processing, budget constraints, flexibility, scalability, and more.

Quicktron's comprehensive suite of G2P automation solutions includes:

QuickBin: A two-robotic bin-to-person solution that revolutionizes order fulfillment all while maximizing vertical space utilization by up to 75%. It elevates goods to heights of up to 27.2 feet, significantly expanding storage capacity and streamlining order fulfillment processes. By bringing items directly to the picker's workstation, QuickBinTM dramatically reduces picking times and enhances order accuracy, making it an ideal solution for high-density, high-volume order fulfillment operations.

Shelf-to-Person: It’s a typical G2P system in which goods are stored on racks in horizontal layouts, with robots delivering entire shelves to workstations. Perfect for efficient, high-volume multi-order item processing.

Hybrid G2P: A seamless merger of QuickBin and shelf-to-person systems. This innovative solution offers unparalleled flexibility, accommodating goods of all sizes and volumes processed through centralized workstations. Unlock a new era of efficiency and choice, redefining the possibilities in warehouse automation.

The Applications of Warehouse Robots

Robots streamline warehousing processes, enhancing efficiency and precision. They automate repetitive tasks, freeing up labor for value-added activities. Manual or traditional methods are outdated and time-consuming, but robots provide agility and flexibility. Contemporary warehouse robots offer diverse use cases for optimal operations.

Picking: Robots bring the goods to the picker directly at workstations streamlining order fulfillment. This not only increases accuracy and throughput but also reduces unproductive walking time searching for goods.

Inventory Management: Robots strategically store goods on storage racks based on demand history, optimizing inventory control.

Putaway: Robots swiftly identify incoming products, autonomously transporting them to designated storage locations, optimizing efficiency and space utilization.

Returns Management: Warehouse robots streamline return processing by automating tasks such as receiving, sorting, inspection, and restocking, improving efficiency, and accuracy, and reducing labor costs.

Package routing: -Beyond static conveyors, mobile robots enable flexible routing of completed orders to shipping zones.

Working together in an orchestrated manner, warehouse robots eliminate bottlenecks, minimize errors, and maximize human associate productivity across workflows.

Why Adopt Warehouse Robots?

Adopting warehouse robots brings a multitude of benefits to your warehouse operations. In 2023 we have seen a global rise in shopping activities, as reported by NRF & Proper Insights Analytics, alone in the USA 200.4 million consumers embarked on a shopping spree over the five-day holiday weekend from Thanksgiving Day through Cyber Monday, smashing all previous records. In evolving shopping trends, the need for more flexible and scalable automation is inevitable. The benefits of robotics include:

Increased Productivity: Robots can perform tasks much faster and more consistently than humans, leading to significant productivity gains.

Reduced Labor Costs: Robots can automate repetitive tasks, freeing up human workers for more value-added activities, and reducing labor costs.

Improved Accuracy: Robots minimize errors, ensuring order fulfillment and inventory management accuracy.

Space Optimization: Robots can maximize storage capacity by utilizing vertical space and optimizing aisle configurations.

Enhanced Safety: Robots can handle hazardous materials and perform tasks in dangerous environments, reducing workplace risks.

Benefits of Embracing Robotic Automation

If you automate picking processes in your warehouse with mobile robots, you’ll be able to:

Furthermore, robots optimize workflows without disrupting your warehouse’s culture. Instead, they add to your culture by improving employee morale and retention. Adjusting business processes is minimal. And seamless integrations with existing warehouse management systems and equipment keep implementation risk-free and fast.

Preparation for Robotic Adoption

For Quicktron Robots, you don’t have to make many big changes to your warehouse. In fact, the infrastructure changes are minimal with scalability for future expansions as well. We evaluate your warehouse layout to perfectly accommodate robots and their movements. Also, provide hands-on training to familiarize workers with robots and their role in the workflow.

Conclusion

Warehouse robots are not only revolutionizing the logistics sector but also influencing the future of work. Integrating them into warehousing operations is a means to enhance operational efficiency using powerful, flexible, and scalable systems. Quicktron robots, with seamless integration, can transform your warehouse into a productivity hub, reducing cycle time and propelling operations to new heights. Embrace the future of warehousing and initiate the conversation to introduce robotic coworkers to your associates.

Ready to welcome new robotic coworkers? Let's start the conversation.

Get More Insights about our Goods-to-Person System at https://www.quicktron.com/solutions

Download the QuickBin Booklet for profound understanding https://www.quicktron.com/downloads

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.