AI-driven Automation: Mobile Robotics as a Catalyst for Green Manufacturing

In today's rapidly evolving world, the pursuit of sustainability has become more crucial than ever. Industries across the globe are grappling with the need to reduce their environmental footprint, and manufacturing is no exception. While the manufacturing sector has historically been associated with pollution and resource depletion, there is a transformative force at play that promises to change the game – AI-driven automation, particularly through mobile robotics. Quicktron Robotics is harnessing the power of artificial intelligence (AI) and mobile robots to revolutionize manufacturing and pave the way for a greener future.

The Environmental Imperative

Before delving into the role of AI-driven robotic automation, it's essential to understand the environmental challenges that the manufacturing sector faces. Traditional manufacturing processes are often resource-intensive, leading to excessive energy consumption, waste generation, and carbon emissions. These practices not only harm the planet but also contribute to rising operational costs.

The urgency to address these issues has led to a paradigm shift in the manufacturing industry. The quest for sustainable practices and green manufacturing has given birth to innovative solutions that aim to mitigate environmental impact while maintaining operational efficiency.

AI and Mobile Robotics: A Powerful Duo

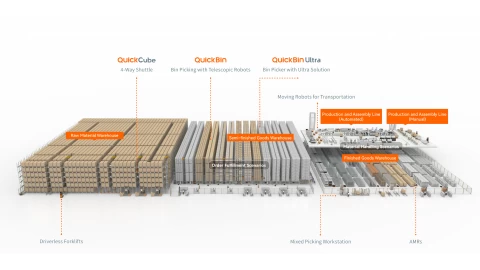

Enter AI-driven automation, a cutting-edge technology that combines the power of artificial intelligence and mobile robotics to streamline manufacturing processes. Quicktron Robotics, a leading player in this space, is at the forefront of this transformation. Our advanced mobile robotic systems are not only redefining productivity but also contributing significantly to sustainable manufacturing practices.

1. Resource Optimization

One of the primary ways AI-driven automation, using mobile robots, aids in green manufacturing is through resource optimization. Mobile robots are highly specialized in optimizing resource utilization within manufacturing facilities, distribution centers, and warehouses. These robots excel in the efficient movement and management of goods, contributing significantly to resource optimization.

Firstly, these mobile robots are experts in materials handling and space optimization. They autonomously transport goods, components, and inventory to precise locations, eliminating inefficiencies associated with manual material handling and reducing the need for excess inventory storage. By optimizing the flow of materials, they ensure that resources are readily available when and where they are needed, minimizing both space requirements and inventory costs.

Secondly, robots play a pivotal role in streamlining workflow and reducing downtime. They can perform tasks such as picking, packing, and transporting items with speed and precision, ensuring continuous production or order fulfillment. This reduces resource waste associated with idle machinery and labor downtime, ultimately improving operational efficiency.

Lastly, mobile robots contribute to resource optimization through data-driven insights. Equipped with sensors and cameras, they collect data on inventory levels, product movements, and facility operations. This information is used for real-time decision-making and long-term planning, enabling better resource allocation, inventory management, and process optimization. In essence, mobile robots are key players in resource optimization within manufacturing and logistics operations, making processes more efficient, cost-effective, and adaptable to changing demands. As a result, manufacturers can significantly decrease their environmental footprint and operating costs simultaneously.

2. Waste Reduction

Traditional manufacturing often generates substantial amounts of waste, leading to environmental pollution and higher disposal costs. Quicktron's mobile robots, when combined with AI-driven automation, can be programmed to collect and transport waste materials to recycling or disposal areas efficiently. As our robots offer a 99.99% accuracy in material handling tasks the chance of resource wastage during manufacturing intralogistics is minimal. This not only reduces the environmental impact but also enhances overall cleanliness and safety in the manufacturing environment all while saving substantial cost.

3. Energy Efficiency

Utilizing AI algorithms, Quicktron Mobile robots are adept at analyzing energy consumption patterns and executing real-time adjustments to optimize energy utilization within manufacturing facilities. These robots achieve significant reductions in energy consumption through a comprehensive set of strategies. This includes the implementation of efficient motion planning and trajectory optimization to minimize unnecessary accelerations and decelerations, as well as the utilization of low-power sensors and regenerative braking mechanisms. Intelligent battery management systems are integrated to monitor battery health and fine-tune charging and discharging cycles.

Furthermore, intelligent task scheduling algorithms are employed to group similar tasks together, thus diminishing the necessity for frequent start-stop cycles and energy-intensive transitions. Moreover, the robots adapt their speed and behavior in response to their surroundings, such as slowing down in congested areas or when navigating obstacles, further solidifying their commitment to energy efficiency.

By employing these methods, robots can minimize energy wastage during navigation, data collection, and task execution, ultimately extending their operational lifespan, reducing operating costs, and contributing to a more sustainable and environmentally friendly robotic ecosystem.

4. Predictive Maintenance

Quicktron's AI-powered mobile robots are equipped with predictive maintenance capabilities as well. They can move autonomously through the manufacturing floor, collecting data from sensors and performance metrics. By analyzing this data, they can predict when maintenance is required, preventing unexpected breakdowns and minimizing downtime. This proactive approach ensures smoother operations, extends the lifespan of manufacturing equipment, and reduces the need for replacements.

5. Sustainable Supply Chains

AI-driven automation, with mobile robots as key players, extends beyond the factory floor. Mobile robots can optimize supply chain logistics, reducing the carbon footprint of transportation and distribution. By enhancing inventory management and demand forecasting, companies can minimize overproduction and reduce the environmental impact of excess inventory disposal.

Challenges and Barriers

Despite the myriad benefits, adopting AI-driven automation and mobile robotics in manufacturing may come with its own set of challenges and barriers. These include initial investment costs, workforce adaptation, and potential technological limitations. Manufacturers must carefully plan and strategize to overcome these hurdles and reap the full benefits of green manufacturing.

The integration of AI-driven automation does not mean a replacement of the workforce. Instead, it complements human labor. Manufacturers should invest in upskilling and reskilling programs to ensure that employees can effectively collaborate with AI-powered systems.

Consumer Preferences

Consumers are increasingly making choices based on environmental considerations. Manufacturers that embrace green practices and communicate their commitment to sustainability are likely to attract eco-conscious consumers. Meeting consumer demand for sustainable products is not just an ethical choice but also a competitive advantage.

The Road Ahead

The integration of AI-driven automation, with a focus on mobile robotics, in manufacturing holds immense promise for a greener future. Quicktron Robotics is leading the charge by providing innovative solutions that not only enhance productivity but also align with sustainability goals. As industries worldwide strive to reduce their environmental impact, AI-driven automation, with mobile robotics at its core, will play a pivotal role in reshaping manufacturing practices.

Manufacturers who embrace this technology are not only making environmentally responsible choices but are also poised to enjoy substantial cost savings and increased competitiveness in the global market. AI-driven automation, with mobile robotics as its driving force, is a catalyst for change, transforming manufacturing into a sector that is not just efficient but also environmentally responsible. It's a win-win for businesses, consumers, and the planet.

In conclusion, as we navigate the challenges of the 21st century, AI-driven automation, with mobile robotics as its cornerstone, is emerging as a transformative force in the manufacturing sector. Quicktron Robotics and similar innovators are demonstrating how technology can drive sustainable practices while improving operational efficiency. Green manufacturing is no longer a distant dream but a tangible reality, thanks to the synergy between artificial intelligence, automation, and mobile robotics.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.