Quicktron X Red Sun

Inner Mongolia Grassland Red Sun Food Co., Ltd. is a specialized seasoning company integrating R&D, production, and sales. As a leading enterprise in the seasoning industry, Red Sun Food Group continuously pursues technological innovation and production efficiency. They have introduced Quicktron's robotic solution to achieve full automation in seasoning production, highlighting Quicktron's unique advantages in the food seasoning industry.

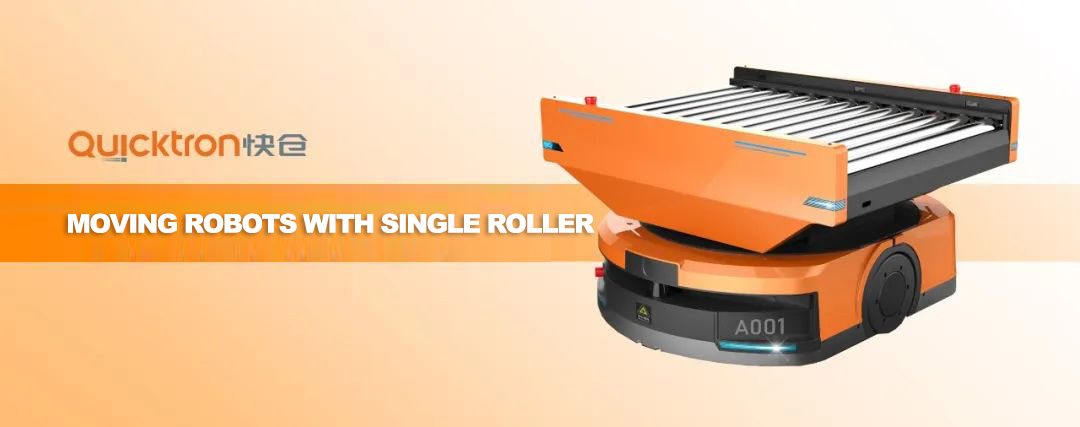

- In the third phase of their smart factory project, 22 units Quicktron roller moving robots were introduced to automate the entire process of raw material batching, feeding, and empty barrel recycling and cleaning.

- This setup enables an annual output of 60,000 tons per shift, with a roughly 50% increase in workforce efficiency.

Challenges And Objectives

| Layout | 20 Material Delivery Points | |

| Layout 20 Material Delivery Points | ||

| 70 Automatic Ingredient Mixing Points | ||

| 5 Soup Ingredient Delivery Points | ||

| 10 Empty Barrel Recycling Points | ||

| 2 Washing Material Delivery Points |

Features:In this project, it is crucial to enforce a forced sorting of task combinations at the feeding points, ensuring precise ingredient delivery according to the batching sequence.At the destination, the AGV's front end must orient towards specific functional areas, ensuring accurate connection with the target position.

Solution and Benefits

Quicktron's AGV solution enhances seasoning production efficiency

- Customized Professional Design: Quicktron has specifically designed a robot solution tailored for the seasoning food industry, catering to customer requirements. The robots are crafted from food-grade stainless steel with washable drawers to meet hygiene standards. They feature rubber-coated rollers to increase friction with materials. Careful adjustments in equipment size and navigation ensure seamless integration into seasoning production environments.

- Stable and Reliable Performance: Quicktron robots boast a stable mechanical design enabling them to navigate complex surfaces, swiftly overcoming obstacles and slopes. Their overall performance has been enhanced by 80%, achieving speeds of up to 2m/s, significantly boosting production efficiency.

-

Safety Measures: To ensure operational safety, Quicktron robots are equipped with multiple safety features including radar, safety bumpers, and emergency stop switches. Moreover, the roller feeding and unloading areas are equipped with short electric rollers to ensure stable docking, with the AGV capable of on-site rotation at the junction, enhancing planning flexibility and efficiency.

- Versatile Application Scenarios: Quicktron employs modular design, allowing customization to suit various seasoning production needs. Its flexible navigation and communication methods enable adaptation to diverse environments.

"By offering competitive intelligent transport solutions to the seasoning food industry, Quicktron has addressed critical challenges and pain points for the Red Sun Group. These include high labor costs, strict hygiene requirements in production environments, low production efficiency, and safety hazards. The implementation of fully automated production processes has significantly enhanced productivity and product quality, injecting new vitality into the company's growth."

Red Sun

Related Cases