From Peak Season Pressure to Year-Round Performance

How early operational planning builds lasting warehouse resilience

Peak season pressure may ease once order volumes return to normal—but the operational lessons it reveals should not be overlooked.

For many warehouses, last year’s peak exposed familiar challenges: labor shortages, unstable throughput, replenishment delays, and limited flexibility when volumes surged. While these issues often surface during peak periods, their root causes usually exist year-round.The most competitive operations are not those that simply endure peak season—but those that transform peak-season pressure into long-term performance improvements.

Why Early Post-Peak Planning Creates Real Advantage

The period immediately after peak season is when operational data is most accurate and decisions can be made without urgency. Acting early enables warehouse leaders to:

- Identify structural bottlenecks rather than temporary overload

- Evaluate labor dependency under peak conditions

- Redesign workflows before the next demand surge

- Plan automation in phases instead of reacting under pressure

Peak season should be treated not just as a challenge—but as a clear indicator of where operations need reinforcement.

Step 1: Review Where Operations Were Most Stressed

Instead of reviewing every process, focus on the areas that showed the greatest strain during peak periods:

- Order fulfillment throughput under high volume

- Picking efficiency and error rates as labor intensity increased

- Replenishment speed between storage and picking zones

- Space utilization when inventory levels peaked

These insights reveal whether limitations were caused by labor availability, storage structure, or process design.

Step 2: Identify the Bottleneck That Limits Scalability

Peak season rarely fails everywhere at once. More often, a single constraint defines the upper limit of performance. In many fast-moving warehouses, that constraint appears in order picking capacity—where manual processes struggle to scale with demand fluctuations. In others, it lies in storage density and internal transport, where space and replenishment speed limit throughput.

Understanding which constraint matters most determines the right improvement path.

Turning Insights into Action with Quicktron Solutions

Once bottlenecks are clearly defined, targeted automation can convert last year’s challenges into this year’s operational strengths.

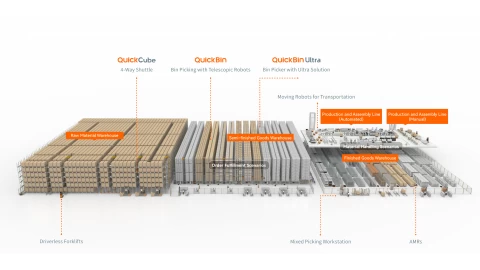

Enhancing Peak Picking Performance with QuickBin Ultra

For warehouses where peak-season stress centers on picking speed, labor availability, and order accuracy, QuickBin Ultra provides a scalable goods-to-person solution designed for high-throughput operations.

By decoupling picking performance from manual labor constraints, QuickBin Ultra helps operations:

- Stabilize order fulfillment rates during demand spikes

- Reduce reliance on temporary labor

- Improve picking accuracy under pressure

- Scale capacity without reconfiguring the entire warehouse

This makes it particularly effective for e-commerce and omni-channel environments facing frequent peak cycles.

👉 Learn more about QuickBin Ultra: https://www.quicktron.com/en_US/landing/quick-bin-ultra

Building Long-Term Storage Resilience with QuickCube

For operations where peak season reveals space limitations, slow replenishment, or rigid storage layouts, QuickCube addresses the challenge at a system level.

As a high-density, modular automated storage solution, QuickCube enables warehouses to:

- Maximize storage capacity within existing footprints

- Maintain efficient replenishment even at high inventory levels

- Support flexible expansion as business volumes grow

- Create a stable foundation for long-term operational resilience

Rather than solving peak challenges temporarily, QuickCube helps organizations prepare structurally for future growth.

👉 Learn more about QuickCube: https://www.quicktron.com/en_US/landing/quick-cube

From Seasonal Stress to Sustainable Performance

Peak season exposes operational limits—but it also offers a clear roadmap for improvement.

By analyzing post-peak performance early, identifying the most critical bottlenecks, and applying automation where it delivers the greatest impact, warehouses can move beyond reactive planning.

With scalable picking solutions like QuickBin Ultra and high-density storage systems like QuickCube, peak season pressure becomes an opportunity—not just to recover, but to perform better all year round.

Overseas Digital Marketing Specialist at Quicktron, specializing in global brand communication, digital marketing and content creation for intelligent robotics and logistics automation.