Transforming Inbound Logistics with QuickCube

The QuickCube Solution: A Deep Dive into Seamless Efficiency

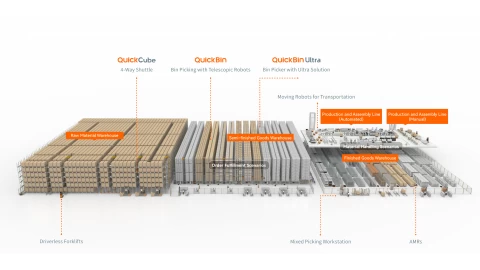

Transforming Inbound Logistics: A comprehensive view of Quicktron Robotics' QuickCube Standard Scenario

Inbound logistics, the critical first step in the warehouse process, can often become a significant bottleneck, hindering overall operational efficiency. The complexity of receiving, processing, and storing goods can lead to delays, errors, and increased costs. However, with the advent of advanced robotics and automation, companies are now empowered to transform these challenges into opportunities for seamless efficiency. Quicktron Robotics' QuickCube is a prime example of such a transformative solution, offering an intelligent system that streamlines every step of the inbound process, from workstation inbound to final storage.

This article delves into the common challenges of inbound logistics and explores how the QuickCube Standard Scenario provides a comprehensive and effective solution. Through a detailed analysis of its features, a comparative look at the competitive landscape, and an examination of its real-world applications, we will illustrate how QuickCube is revolutionizing inbound logistics for modern warehouses.

The Inbound Logistics Bottleneck: Common Challenges in Modern Warehousing

The efficiency of a warehouse is heavily reliant on its inbound logistics. However, this process is often plagued by a series of challenges that can have a cascading effect on the entire supply chain. These challenges include:

• Inefficient Space Utilization: Poorly organized storage and inefficient use of vertical space can lead to a crowded and disorganized warehouse, making it difficult to locate and retrieve goods.

• Manual and Error-Prone Processes: Manual handling of goods is not only labor-intensive but also prone to human error, leading to inaccuracies in inventory records and misplaced items.

• Low Throughput and Bottlenecks: Inefficient receiving and putaway processes can create bottlenecks, slowing down the entire inbound operation and causing delays in the availability of goods for order fulfillment.

• Lack of Traceability: Without a robust tracking system, it can be challenging to maintain real-time visibility of inventory, leading to stockouts, overstocking, and difficulties in locating specific items.

• Labor Shortages and High Costs: The physically demanding nature of warehouse work, coupled with a shortage of skilled labor, can drive up labor costs and make it difficult to maintain a consistent workforce.

The QuickCube Solution: A Deep Dive into Seamless Efficiency

The QuickCube Standard Scenario by Quicktron Robotics is an end-to-end pallet storage and picking solution that directly addresses the challenges of inbound logistics. It combines the power of a 4-Way Shuttle system for high-density storage with the intelligence of Autonomous Mobile Robots (AMRs) for smart transportation. This integrated approach creates a seamless and efficient workflow that optimizes every step of the inbound process.

The 4-Way Shuttle system is an automated material handling solution that maximizes warehouse storage and retrieval. It moves horizontally within a single-layer racking system, transporting pallets between storage positions and lift systems or conveyors. This system is ideal for industries with high demands for high-density storage and efficient pallet handling. The AMRs, on the other hand, provide smart transportation, seamlessly coordinating with the 4-Way Shuttles to move goods from the inbound workstation to their designated storage locations.

The QuickCube system boasts impressive metrics that highlight its effectiveness:

| Metric | Improvement |

| Storage Capacity Increase | 50% - 200% |

| Efficiency Improvement | 200% - 300% |

| Accuracy | 99.99% |

| ROI | 3-4 years |

By automating the inbound process, QuickCube significantly reduces manual handling, minimizes errors, and maximizes throughput. The system's ability to intelligently determine the optimal inbound method, whether it's full-pallet inbound or piece picking, further enhances its efficiency and flexibility.

Real-World Applications: Where QuickCube Excels

The QuickCube Standard Scenario is particularly well-suited for a variety of industries and applications, including:

• High-Volume Inbound Operations: Facilities that receive a large volume of goods on pallets and require rapid processing and putaway.

• High-Density Storage Needs: Warehouses with limited space that need to maximize their storage capacity.

• Frequent Inventory Turnover: Environments with a high rate of inventory turnover that require efficient storage and retrieval processes.

• Temperature-Controlled Environments: The 4-Way Shuttle system is suitable for use in cold storage environments, making it ideal for the food and beverage and pharmaceutical industries.

• Industries Demanding High Accuracy and Traceability: Industries such as pharmaceuticals and high-value goods, where inventory accuracy and traceability are critical.

Conclusion

Inbound logistics no longer needs to be a bottleneck in the warehouse. With solutions like Quicktron Robotics' QuickCube Standard Scenario, companies can transform their inbound operations into a seamless, efficient, and highly accurate process. By combining the power of 4-Way Shuttles and AMRs, QuickCube provides a comprehensive, end-to-end solution that addresses the most pressing challenges of modern warehousing. As the demand for faster, more accurate, and more efficient logistics continues to grow, solutions like QuickCube will become increasingly critical for success.