From Factory Floors to Fulfillment Centers: The Rise of Mobile Robots in Manufacturing and Logistics

The industrial landscape is undergoing a transformation. Massive, hulking robots have long been a fixture in car factories, but a new generation of mobile robots is making waves across the entire manufacturing and logistics spectrum. These nimble machines are reshaping the way we move materials, assemble products, and deliver goods.

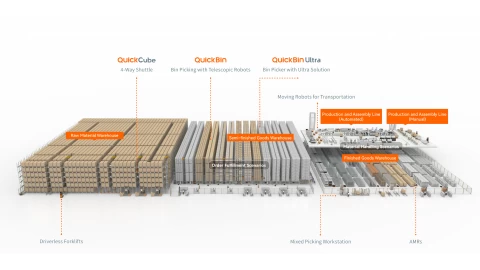

Quicktron Robotics: Powering the Future of Mobility

At the forefront of this revolution is Quicktron Robotics, a leading developer of innovative mobile robot solutions designed to empower manufacturers and logistics providers. Quicktron's AMRs are built with cutting-edge technology and user-friendly interfaces, making them a powerful tool for businesses of all sizes.

What are Mobile Robots?

Mobile robots, also known as Autonomous Mobile Robots (AMRs), are essentially self-driving vehicles designed for indoor use. Equipped with sensors, cameras, and advanced software, AMRs navigate their environment autonomously, avoiding obstacles and following designated paths. Unlike their industrial robot cousins who are confined to a specific location, AMRs are free to roam, making them ideal for tasks that require movement and flexibility.

The Benefits of AMRs

Integrating AMRs into your operations can yield a multitude of benefits:

• Enhanced Efficiency: AMRs streamline workflows by automating repetitive tasks like material handling and parts transportation. This frees up human workers to focus on higher-value activities and keeps production lines running smoothly.

• Improved Accuracy: AMRs operate with precise movements and can be equipped with vision systems for error-free picking and quality control inspections, leading to a significant reduction in errors and improved product quality.

• Increased Productivity: AMRs can operate tirelessly, 24/7, without breaks or fatigue. This translates to increased production output, faster order fulfillment times, and a boost to your overall bottom line.

• Enhanced Worker Safety: AMRs can handle heavy loads and operate in hazardous environments, reducing the risk of injuries for human workers.

• Optimized Space Utilization: Unlike traditional conveyor systems, AMRs are highly adaptable and can navigate tight spaces. This allows for better space utilization within your facility.

Transforming Manufacturing and Logistics with Quicktron Robotics

Quicktron Robotics' AMRs offer a powerful suite of solutions that can significantly improve efficiency and productivity across your entire operation, from the factory floor to the fulfillment center:

Goods-to-Person Systems in Warehousing: Imagine a warehouse where shelves carrying goods come directly to pickers, eliminating wasted time and effort spent walking long distances. Our goods-to-person AMR systems make this a reality. AMRs retrieve shelves or totes containing the required items and deliver them directly to picking stations, allowing workers to focus on picking and packing orders with greater speed and accuracy.

Case Study: Optimizing Warehouse Operations with Goods-to-Person - A leading fashion brand Urban Revivo, deployed Quicktron's goods-to-person AMR system. The results? A 30% reduction in picking time, handling 100,000 inventory per day and a significant increase in order throughput. Workers reported increased satisfaction due to less fatigue and a more ergonomic work environment.

Enhanced Manufacturing with Mobile Robots: In the fast-paced world of manufacturing, keeping production lines running smoothly is critical. Quicktron's AMRs can automate various tasks within the manufacturing process, such as moving freely around the production line, performing tasks like:

- Material Handling: AMRs can transport raw materials, parts, and subassemblies between workstations and production lines, ensuring a steady flow of materials and eliminating delays caused by manual material handling.

- Assembly Line Support: AMRs can assist with sub-assembly tasks, transporting parts and tools between workstations, ensuring a smooth and efficient production flow.

- Effortless Transportation and Transfer: Utilization of robotic systems for transferring raw materials finished goods, and work-in- progress items. Ensure empty pallet supply and seamless connections with robots managing wrappers, labelers, palletizers, machines, and automated warehouses.

Case Study: Streamlined Production with Mobile Manipulators - An automotive parts manufacturer, Stellantis deployed Quicktron's mobile manipulator AMRs for machine tending on their engine assembly line. The results? A 20% increase in machine uptime and a significant reduction in labor costs associated with manual machine loading. These robots manage large volume and small volume goods, handling 20,000 tasks per day in an extremely complex manufacturing scenario, all while catering workers safety.

The Future of Mobile Robots

The potential of mobile robots continues to grow. As Quicktron Robotics and other industry leaders push the boundaries of technology, we can expect to see AMRs with even greater capabilities:

- Increased Intelligence: AMRs will become more adept at handling complex tasks and making decisions in real-time, further enhancing their contribution to the manufacturing and logistics processes.

- Improved Collaboration: Human-robot collaboration will become more seamless, with AMRs working alongside human workers to achieve optimal efficiency.

- Wider Adoption: The cost of AMRs is decreasing, making them a more accessible solution for businesses of all sizes. This will lead to wider adoption across various industries.

The Changing Workforce

The rise of mobile robots doesn't signal the end of human jobs in manufacturing and logistics. Instead, it represents a shift towards a more collaborative work environment. Human workers will focus on higher-level tasks that require creativity, problem-solving, and critical thinking skills, while AMRs handle the repetitive and physically demanding aspects of the job.

The future of manufacturing and logistics is one where humans and mobile robots work together to create a more efficient, productive, and safer work environment. Quicktron Robotics is at the forefront of this exciting development, and their commitment to innovation ensures that businesses will have the tools they need to thrive in the years to come.

Arslan crafts compelling content, executes social media campaigns, and masters online ads, webinars, podcasts, and copywriting. He builds strong relationships with clients, empowering them with support and resources to achieve their sales goals. Leveraging data insights, he refines strategies and collaborates seamlessly to stay ahead of the digital curve.